Our dogs are not only very hard working members of our farm team, they are also real characters which give us a lot of enjoyment (and strife on a bad day).They hold a special place in our farming community and they are great companions in an often lonely job.

So what can we do to make things better for the team and also improve their performance and fitness to work?

Preventative Health Care – Regular physical exams, vaccinations and diagnostic testing will help detect any early signs of illness and keep your team in top working condition.

Nutrition – One of the most important factors for working dog performance is nutrition. With some dogs running up to 100km/day at speeds of 20-30km/hr, suitable feeding ensures dogs work better for longer. Dogs that are fed appropriate levels of protein with optimal diets c sustain less musculoskeletal injuries. Diets recommended by VSHB are Royal Canin 4800 and Black Hawk Working dog, both of which meet these recommendations. While these diets may be more expensive per bag compared to commercial diets, less needs to be fed to meet the same nutritional requirements and dogs have the energy to work all day.

Worm and Parasite Management – we have a worming programme available for rural clients, delivering worm and flea treatments to you in the post, before they are due.

Insulated kennels elevated off the ground with grating –Draft free well-made kennels are important and are now being used on by most farm. We see lots more farmers using insulation in their kennel walls and roofs to keep the dogs warmer. If you are building new kennels this would be a great idea as it is smart to keep your dog’s warmer in winter as they then use less of the food you give them to just keep warm and more of the food to give them energy to work – a win win situation!

Elevation is really important to keep dogs off the ground as this reduces worm re-infestation from dog pooh. Elevated kennels make cleaning easier and slatted floors allow waste to fall away. Make sure that the slat size is small enough not to cause leg and foot injures and large enough to allow faeces to easily fall through.

Concrete pads make cleaning easier and also helps with environmental control of fleas.

Utilising existing buildings for shelter, planting wind breaks, using shade cloth and attaching corrugated iron over the runs for shade are all reasonably easy ways to limit your dogs exposure to the elements.

Bedding in kennels and dog coats – There is definitely a move towards providing bedding in the kennels and dog coats, especially in the winter and for older dogs who are a bit stiff. Of course previously bedding had a bad reputation for flea infestations but with the new products now available this is no longer the issue due to their persistent effect which effectively breaks the flea life cycle.

Veterinarian Caroline Robertson & husband James Aitken recently upgraded their 4-run kennels for their dogs at Rangitapu Station. They have shared their kennel designs, size and breakdown of costs to help other farms who may be considering new kennels on farm.

The kennels – We based our design around a standard sheet of 5mm ply (2.4m x 1.2m) and covered them with flat iron at the end of the kennel build.

The external dimensions of the set of 4 kennels were;

-

-

- 2.4m long

- 960cm high at the front and 930cm high at the back, creating a a sloping roof

- 1m deep

-

On the inside of the frame we used 20 mm ply (100cm x 50cm rough sawn) and filled the gap between the external walls and the internal walls with wool for insulation.

We decided to use 20 mm tanalised ply for extra strength and wear as this is what the dogs are in contact with.

Kennel Runs

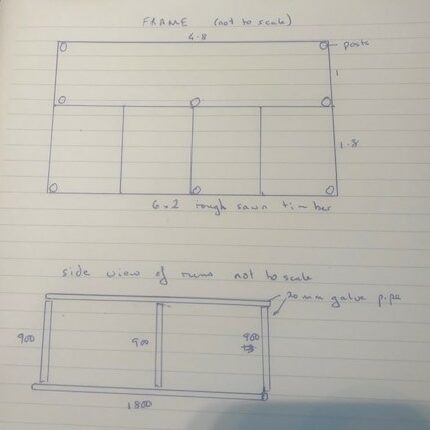

We based the runs around 900mm rolls of diamond mesh and made the 4 run frame out of 20mm pipe so the dogs couldn’t chew it to bits.

The runs are 1.8 m long and 900 high (by that I mean the vertical pipe length is 900 and it is welded on its end to the horizontal 1.8 m pipes – see the photo).

The base/floor is 4.8 m long and 2.8 m deep with joists under each run wall and a further long joist at the metre mark to rest the kennels on We made the frame out of 6×2 rough sawn for strength

The run floor we made from 100 cm x 20 cm rough sawn timber 20 mm apart. We bought 4.8 m lengths from Turtons and bugle screwed them onto the frame and all the joists.

Kennel Frame

We made the frame on the ground then dug in posts on the corners and in the middle and cut them off level 4-500 mm off the ground and lifted the frame up and bugle screwed it onto the posts with 100 mm screws. Then we lifted the kennel set onto the back of the frame with a front end loader and strops and got it lined up exactly. Then we screwed the floor on and then lifted the runs on and slid the up hard against the kennels.

For water we bought concrete dog troughs and depending on your water pressure used very small galv pipe put it on top of the runs and cut it and put a T join in above each trough. The pipe has to be threaded so there is a bit if fiddle work here. We put a 100 mm piece of pipe into the T join to direct the water into each trough. If your pressure isn’t great restrict the flow on each of the down pipes starting with the one closest to the tap until water is flowing out of all of them. I turn the tap on when I start feeding the dogs and by the time they are all fed the troughs are full of fresh water

Total Cost – The total cost with no labour was about $1800 per set. We spotted some pretty flimsy uninsulated kennels (set of 4) going for $8000 at the field days.